Biocompatible materials for medical implants

Stainless steel used for implants must be corrosion-resistant and biocompatible. As implants are always used in the body, it is essential to aim for a high biotolerance when choosing the material.

These implants are usually made of chromium-cobalt-molybdenum alloys, austenitic steels or titanium. The latter is mainly used for patients with a contact allergy (to chromium and nickel).

The in-house CHRONIFER 108 steel is an austenitic stainless steel without nickel. It is ∂ (delta) ferrite-free, non-magnetic and well suited for all applications that require both high strength and good corrosion resistance. These properties make this steel particularly attractive for implants and prostheses for joint replacements.

The following special features make the steel a material that is perfectly suited for medical use (surgery):

- High mechanical properties

- Fatigue resistance

- Corrosion resistance

- Hypo-allergic properties

Other suitable stainless steel grades:

- 1.4441 Implant (AISI 316 LVM)

- 1.4472 Implant (ASTM F-1586)

Areas of application:

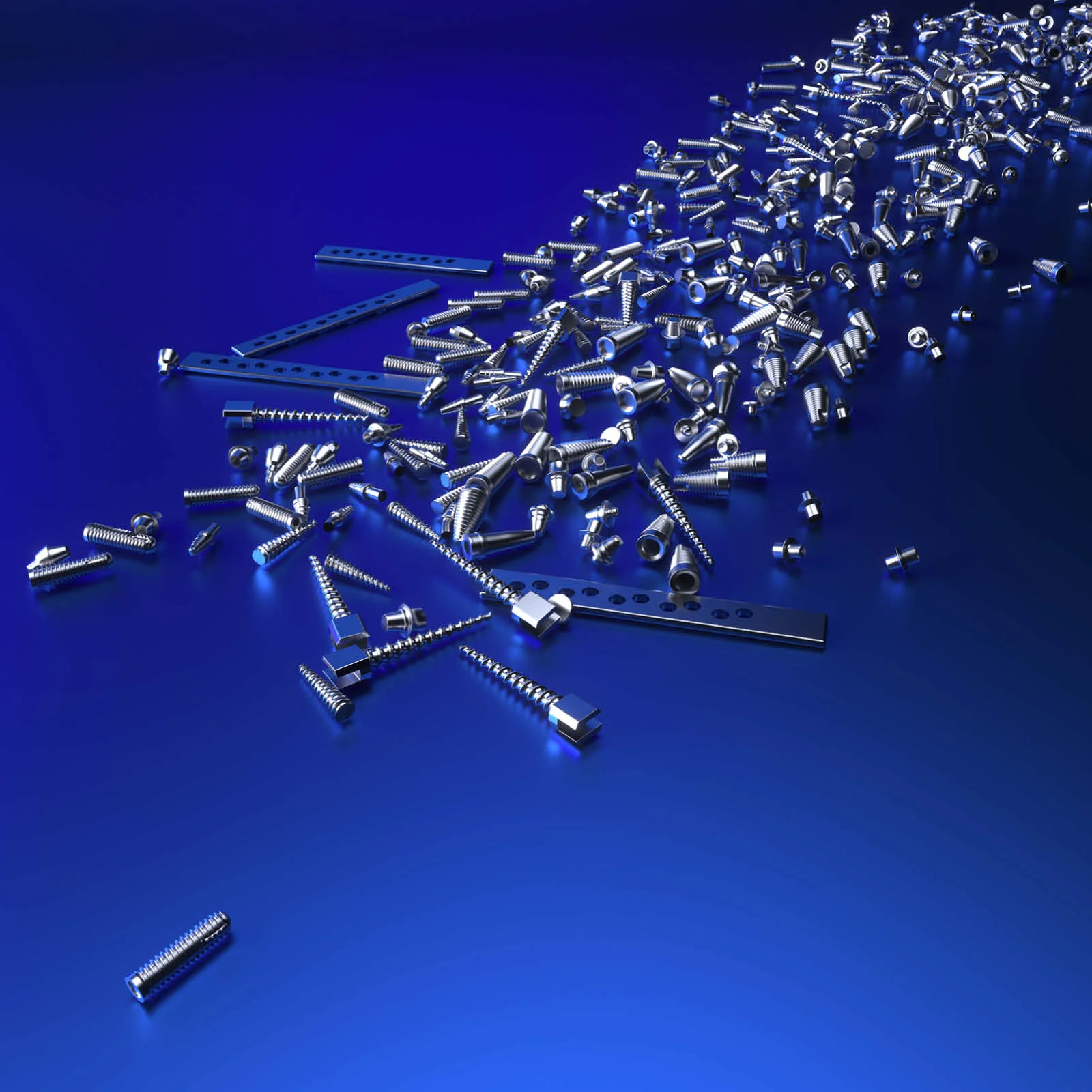

- Osteosynthesis implants

- Spinal implants

- Dental implants

- Orthopaedic implants

In order to be used in these areas, these special steels must meet an excellent standard of micro-cleanliness.

At L. Klein SA, we supply our customers with reliable medical steels. Our sources have been recognised for decades in the field of implantable steels.

The existing stock includes round profiles in bars and rings, which you are welcome to order in small quantities.

Material requests with special requirements are one of our specialities.

In addition to secure shipping, our multilingual customer service and the associated support also speak in our favour. We supply our customers locally ourselves, but as far as possible we use external haulage companies to reach the EU and the whole world.

Give us a call or write to us – we look forward to receiving your order/enquiry.