What is austenitic stainless steel

Austenitic stainless steel is a group of steels that proportionally have higher chromium (> 12%) and nickel content, but a low carbon content. The steel is corrosion-resistant from a chromium content of 12%. For this reason, austenitic steel is the most used stainless steel group.

Properties of stainless austenitic steel

Austenitic steels contain up to 35% nickel and between 16 and 26% chromium. Due to this composition of alloy, they in general have a higher corrosion resistance than for example martensitic steels. The steel is non-magnetic and cannot be hardened by heat treatment.

Austenitic steel grades and applications

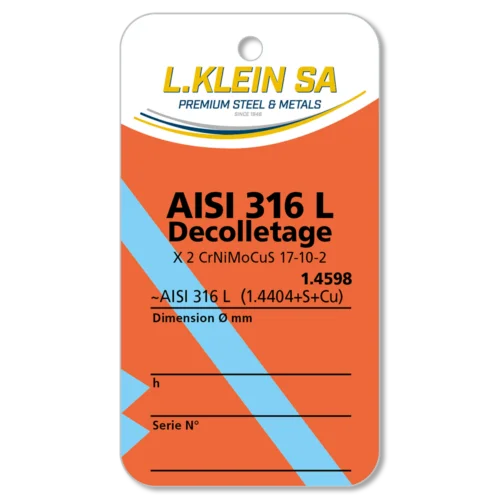

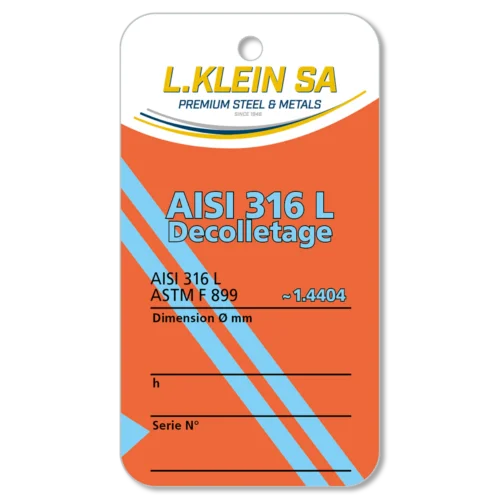

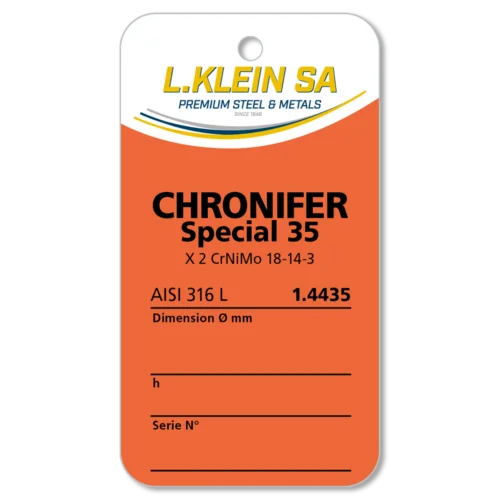

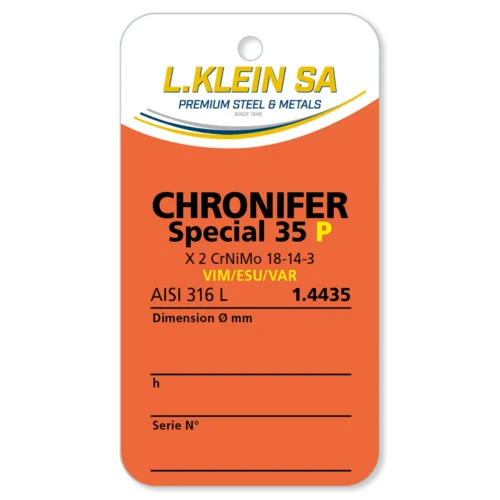

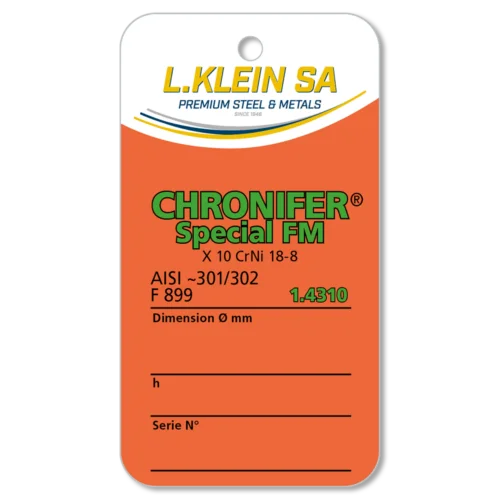

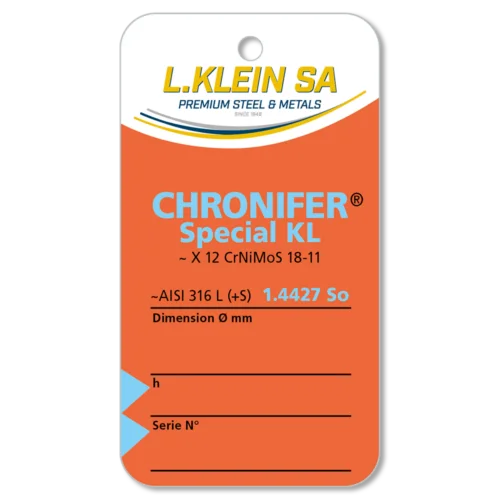

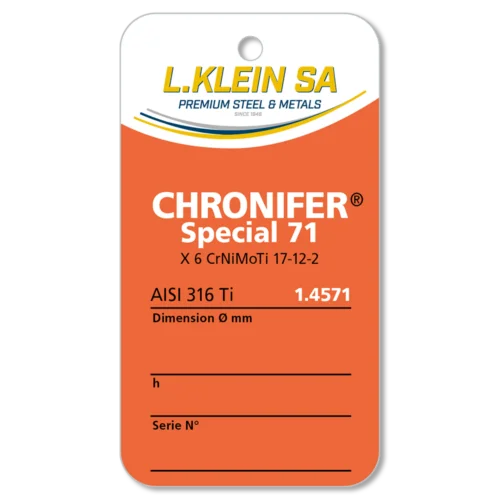

The most popular austenitic steel grades are AISI 302, 303, 304, 304L and AISI 316L, particularly noteworthy are Chronifer Supra (1.4301 / 06/07), Chronifer Special 04 (1.4404), Chronifer Special 35 (1.4435), and 1.4441 Implant (316 LVM ).

Areas of application are watchmaking, food and aircraft industries, but also the medical and dental technology. AISI 316 LVM (1.4441) is often used for temporary implants (plates and screws) and other instruments.

L. Klein SA is a reliable supplier for various qualities of austenitic steel. Here you can buy the steel as rings and rods, even in the smallest quantities, with special requirements (small diameter, intermediate dimensions, tight tolerances). We deliver high quality steels all over the EU and worldwide. The region within 130 km is supplied by our own vehicles.